Version 1.39 - Release Notes

Released September 6th 2023

Remember how we said we had some exciting new features coming up? Well, we are excited to reveal two of them in this version - Construction Guides and Templates! Read on for more information. We’ve also gone through and cleaned up a lot of outstanding bugs so that we can focus on bringing more exciting features in the upcoming versions!

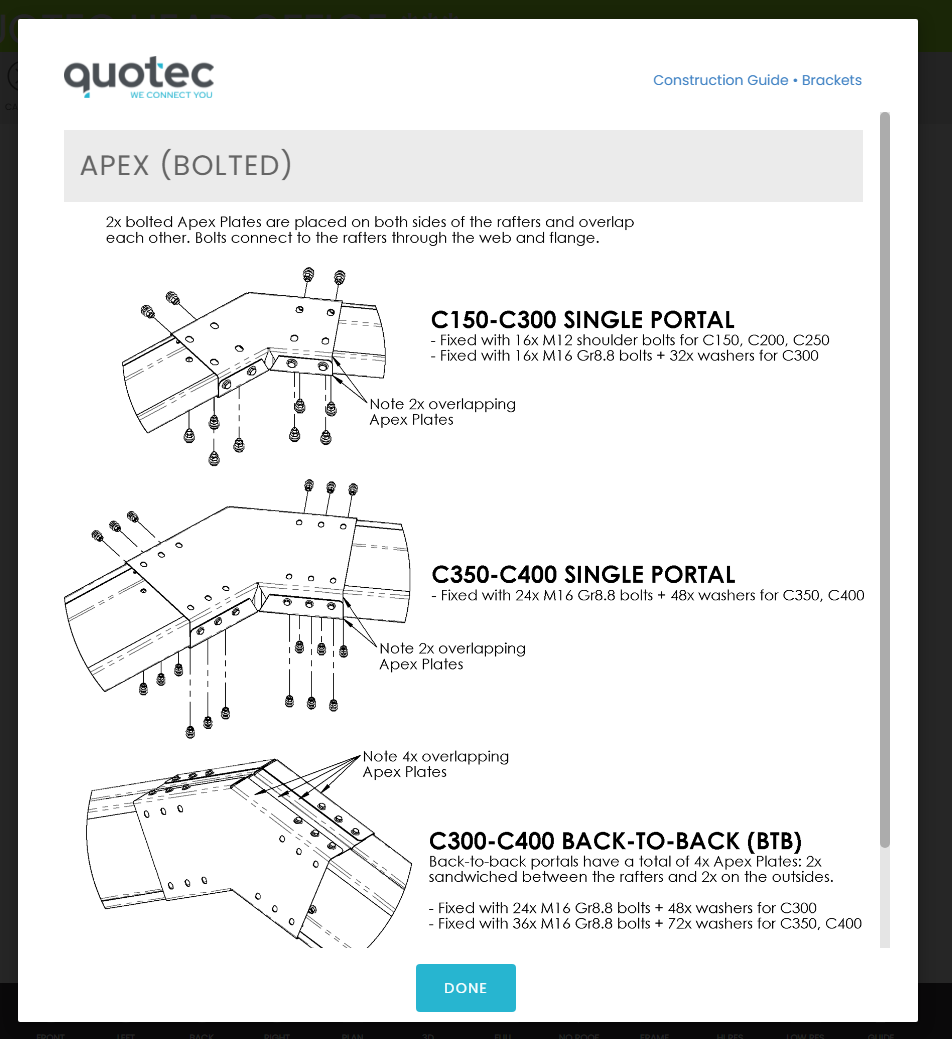

Construction Guides

We have implemented a framework for job specific construction guides as well as designer-based info.

When you quote a job, one of the additional documents that will be generated is a Construction Guide. This will be accessible under the Documents section for the jobs.

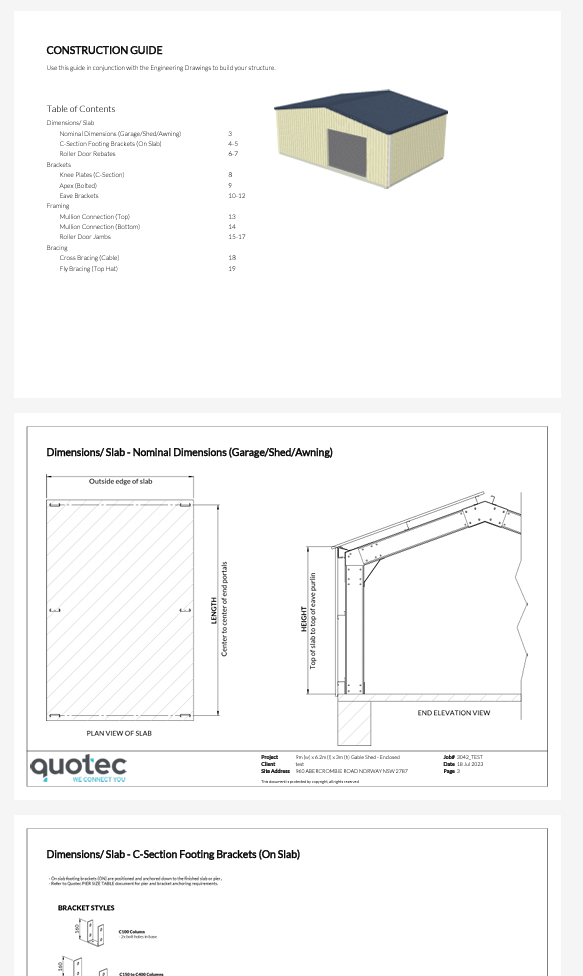

The document itself looks similar to the existing engineering drawings:

The document will only contain information relevant to the job. For example, if the job is a skillion garage, you won’t see information about apex plates.

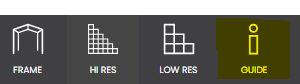

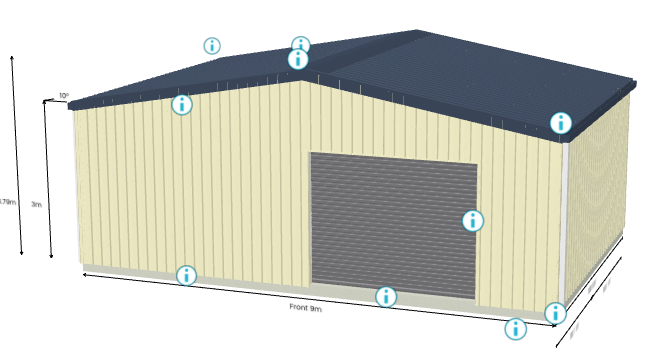

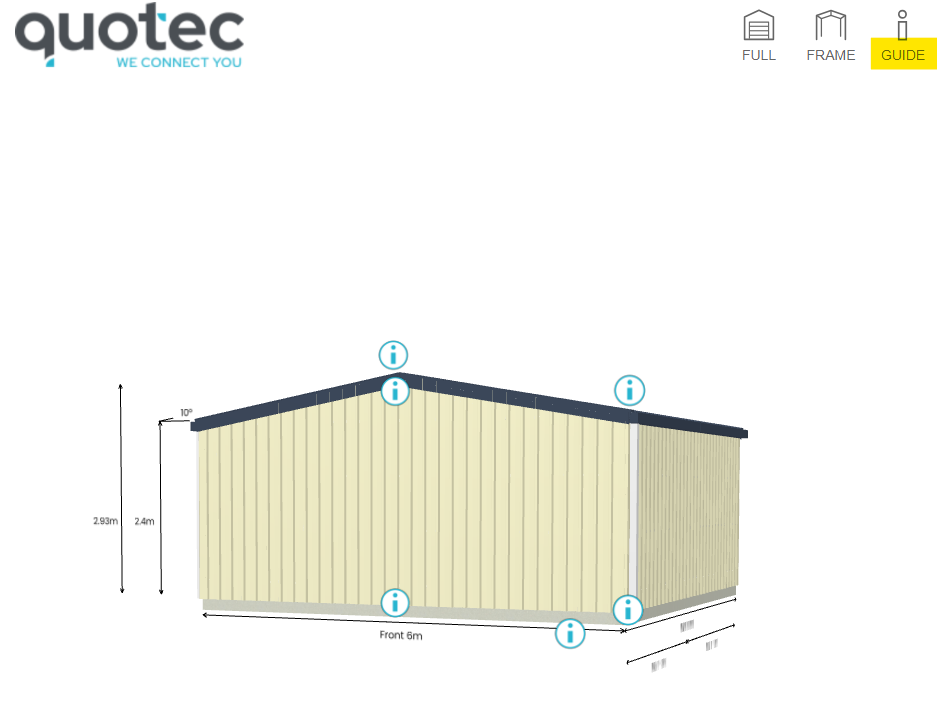

In the designer, there is a new Guide button at the bottom of the screen.

This works as a toggle button. When you press it the first time it will display information icons on the building. When you press it again, the icons will disappear.

When you click on an icon, the designer will show you the construction guide information for the part of the building.

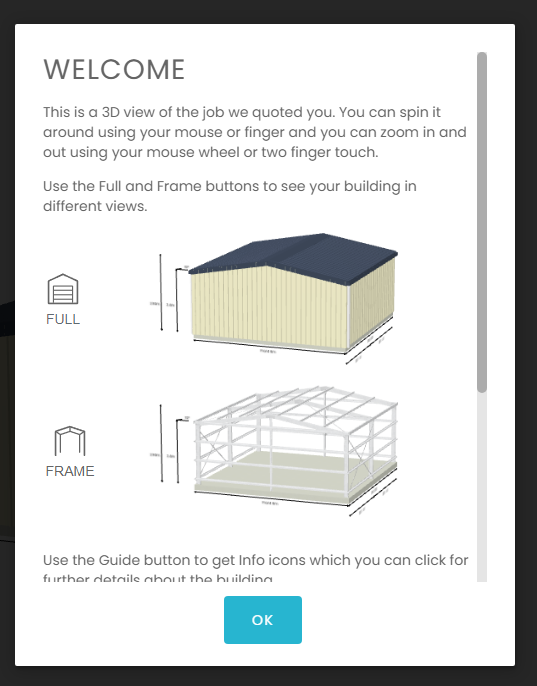

With this new feature we have also taken the opportunity to enhance the 3D link in the proposal email.

When the customer clicks the link they will see this help popup:

They will also have the guide available to them:

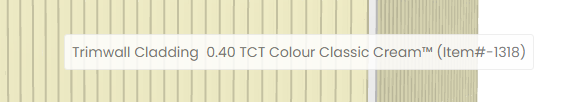

Also, the customer will be able to hold and click on a part of the building to see its details, which will help them when trying to see what part goes where.

Note, this is a work in progress and the guides themselves will be enhanced over coming months. For the moment, construction guides are not available for carports or mezzanines. As well as drawings, we will be adding photos from actual sheds to show how things look in the field.

Note that existing jobs will attempt to create a construction guide but since the job doesn’t have the construction guide tags in it, the guide will be empty. New jobs will create guides correctly.

Templates

You can now create job templates to make it easier to start a common design.

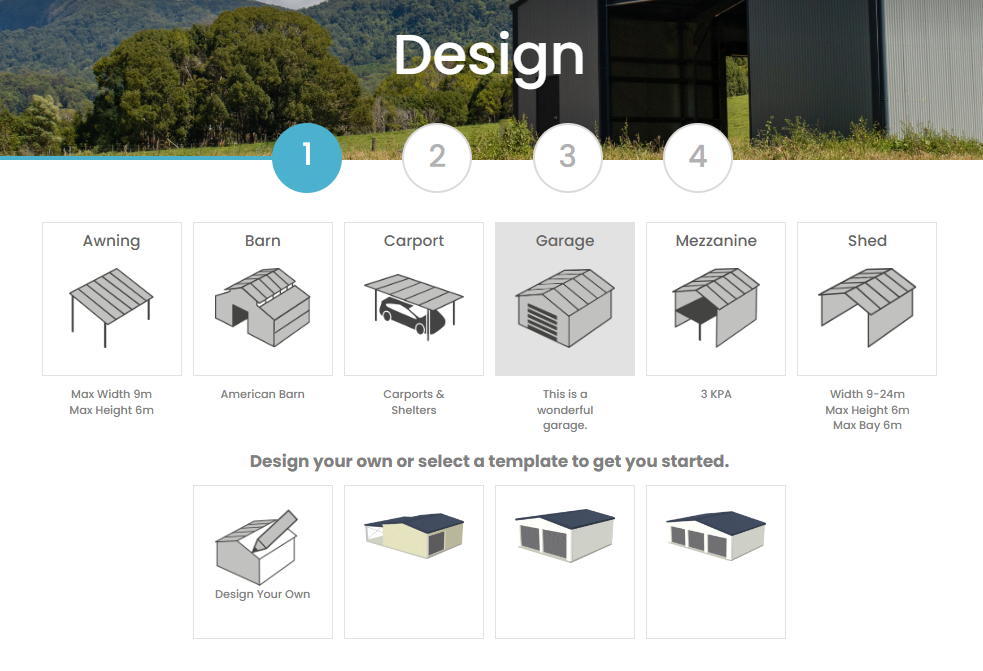

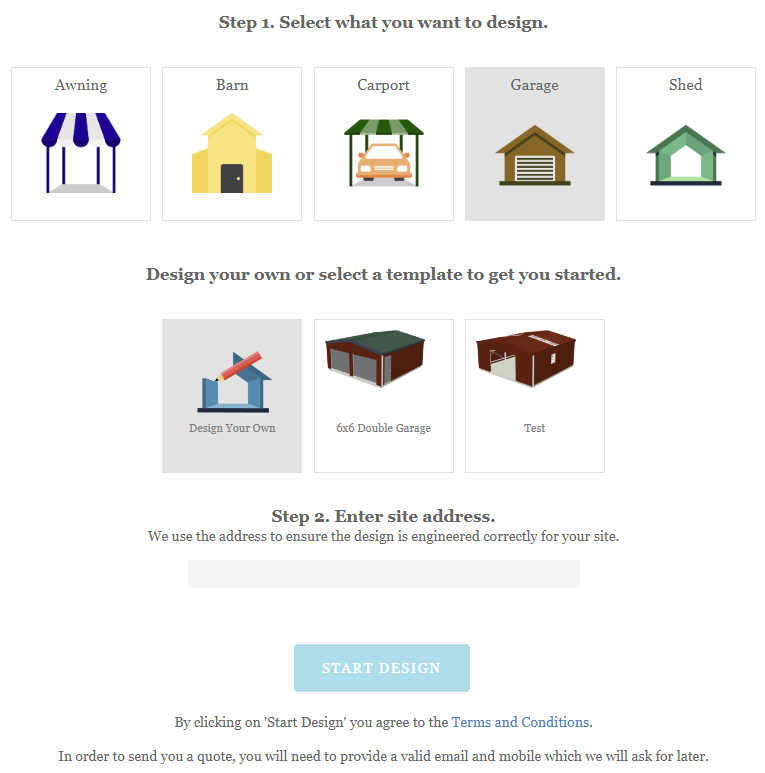

When starting a new job, if you select a building type that has templates, the system will display these options to you.

This is how it will look in Quotec Live:

And in Quotec Now:

You can choose to simply Design Your Own (show a blank building same as it has always done) or select one of the options to get that design as a starting point.

Quotec Now

We have made a number of modifications for Quotec Now.

Templates are now available as discussed above.

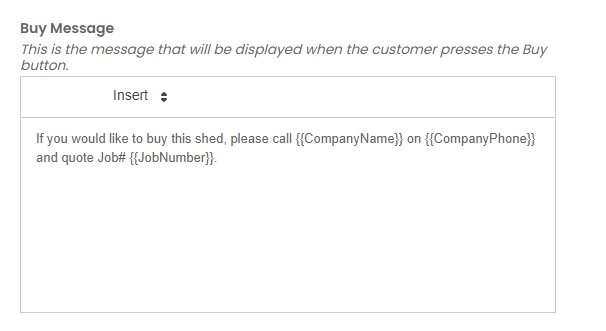

When the user looks at their quoted design they can press the Buy button. The text displayed at this point is now user definable. Go to My Company| View Online Designer and set the Buy Message:

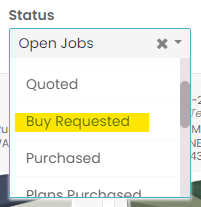

In addition, when the user clicks the Buy button, the status of the job is changed to Buy Request and an email sent to the salesperson so you can follow them up. Check your email types for the new Buy Job Request email and customise it to your needs. You can also search for these jobs:

If a user creates multiple quotes, Quotec will create only the one customer. It will match the customer via email address and the last few digits of the mobile number they enter.

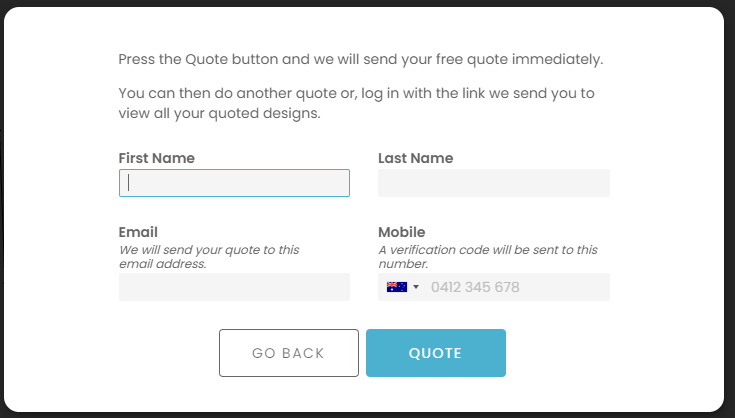

When the customer requests a quote, we display a screen asking for their details.

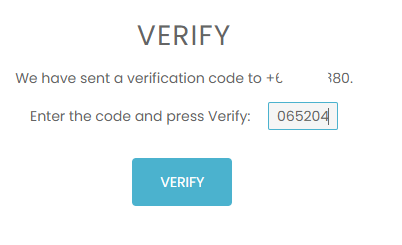

The issue in the past is that there was nothing to stop a user from entering a fake mobile number making it impossible for the salesperson to follow up and try to close the sale. Now when the customer presses the Quote button, we will send a verification code to their mobile and they will need to enter this in order to get the quote. This ensures the mobile is correct and follow up is possible.We have added a Start Again button in the header to make it easier for a customer to restart the design process.

The downpipe options will show the shortest lengths of downpipe so as to not confuse the user with multiple length options.

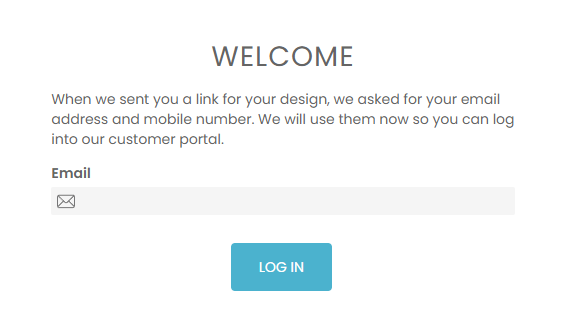

The link that is sent in the proposal email to review their design now leads to a new page. They will be redirected to a Customer Portal page.

Once they enter their email address, they will be asked to enter a verification code.

If successful they will be shown all the designs they have worked on:

They can then click on any of the designs to go to the designer screen.

Over time we intend to provide more features in this Customer Portal, e.g. payment methods, status reports, etc. Note, the link sent for Quotec Live proposals is the same link we have always used to provide a view only option. At some time in the future we may look to make the customer portal available to those users as well.

Roller Door Motors

When adding/editing roller doors, you used to add a motor by checking a checkbox on or off. This has been replaced by a dropdown with options:

No Motor (same as checkbox checked off)

Motor - Either Side (same as checkbox checked on)

Motor - Left Side

Motor - Right Side

Why have we done this? Gliderol (coming soon) add the motor to the roller door before it leaves the factory so it's important to specify to which side you want the motor added. This information will be displayed on the Bill Of Material and Purchase Order.

Enhancements

Users. You cannot add multiple users with the same email address.

Purchase Orders. If you change the address on a purchase order, the system will display a message warning you to check consolidation is correct for associated orders. This is just an information message as some people would say change the fasteners to go to office and not check the Q-Plates order to remove the consolidation fee.

BOM. We have reworked the bolt calculations so that it is much more precise. You should see a significant decrease in the number of bolts ordered when using punched Z-Sections.

Browser. The browser will give a warning when a user tries to use Firefox, which is a non-supported browser. This will be in Quotec LIVE and Quotec NOW.

Metroll do not supply the round metal downpipe so these will not be displayed as an option on a job when Metroll is the supplier.

Certification codes for cladding for NT jobs has been updated.

Mobile mode. Further enhancements have been made to the designer to make usage on a mobile device better.

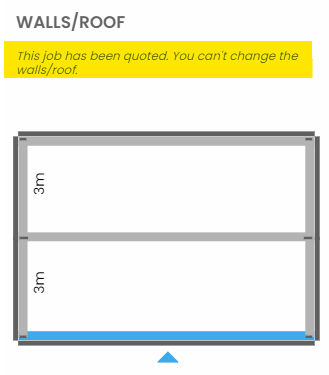

When looking at a quoted job in the designer, we make it clearer that details cannot be changed by displaying messages like this:

Bugs

When knee bracing was required on a skillion garage, the knee brace connection plate on the higher side was incorrect.

On a single bay skillion garage which had an eave extension, the trim angle supplied was too long.

On skillion garages with BTB frames, the higher side eave purlin bracket was incorrect.

When moving windows, you couldn’t move them up into the high end of a skillion wall.

When using horizontal cladding, the designer was not showing the mini tophat properly on the left side of the building when there was a window or door.

In extreme cases where the height of the building changed the design windspeed, purlins were not supplied.

On buildings that had a top curtain wall at the front, there was some flashing provided. Flashing itself was correct but the designer drew it in a funny position making it look weird.

Girts that were in the high side of a skillion wall (above the building height) were not always the correct length.

On buildings with eaves, the purlins directly above the column were not hole punched resulting in an error preventing a quote from being done.

Fixed issue where hole punching was requested with weird negative numbers.

When adding an awning to a building and the awning was invalid, e.g. a window in the way, or height was too small, the system would attempt to show the same error message multiple times resulting in a dark screen of death.

The Copy 3D Link option in the designer was not a valid link.

When trying to create a barn the system would hang.

Openings could not be created in the high side of a skillion.

The Goods Receipt was not showing the job# (it was showing the PO# again).

When a job was marked as quoted, there were a couple of areas where details could be still be changed. These have been locked down.

A roller door which requires say a C150 jamb cannot share a column which is bigger, e.g. C250. The flange of the jamb and column are different and the roller door will not sit correctly.